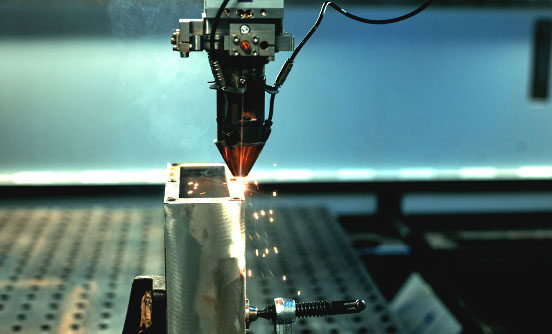

The Advantages of Laser Welding: Precision, Efficiency, and Versatility

Laser welding has emerged as a groundbreaking technology in the field of manufacturing and fabrication, revolutionizing the way industries join materials together. Employing a high-intensity laser beam, this cutting-edge technique offers a host of advantages that have propelled it to the forefront of modern manufacturing processes.

In this article, we delve into the world of laser welding and explore its numerous benefits, ranging from precision and efficiency to versatility and environmental friendliness.

Precision and Accuracy

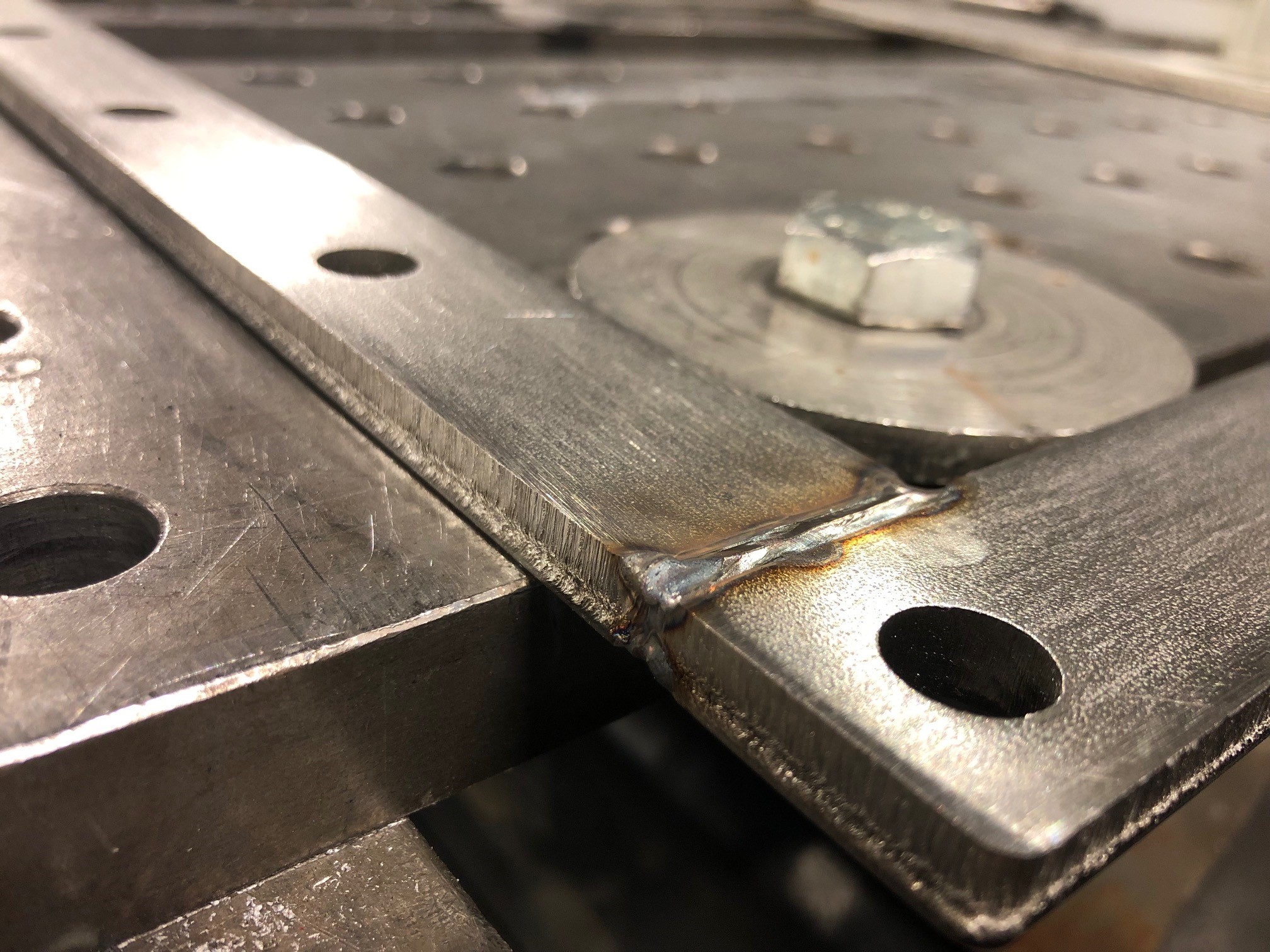

Laser welding stands out for its unparalleled precision and accuracy. The concentrated and highly controlled laser beam allows for micro-welding applications with minimal heat-affected zones (HAZ). This reduced HAZ prevents distortion and material damage, making it ideal for joining intricate components with utmost precision. Industries like electronics, aerospace, and medical devices greatly benefit from laser welding’s ability to achieve seamless and delicate connections.

High Speed and Efficiency

One of the major advantages of laser welding is its incredible speed and efficiency. The focused laser beam rapidly melts the materials, leading to fast and efficient welds. Unlike traditional welding methods, which may require pre-heating and post-processing, laser welding minimizes the need for additional steps, streamlining the manufacturing process and reducing production time. As a result, manufacturers can increase productivity, meet tight deadlines, and remain competitive in the market.

Versatility Across Materials

Laser welding exhibits exceptional versatility, capable of joining a wide range of materials, including metals, plastics, ceramics, and even dissimilar materials. This flexibility makes it an indispensable tool for various industries, from automotive and aerospace to jewelry and electronics. Additionally, laser welding enables multi-material joining, opening up new design possibilities and allowing engineers to create innovative and lightweight structures.

Reduced Distortion and Warping

Conventional welding methods can often lead to distortion and warping due to the high heat input during the process. In contrast, laser welding’s localized heat input and controlled energy transfer significantly reduce the risk of distortions in the welded components. This advantage not only ensures the structural integrity of the final product but also minimizes the need for costly rework or repairs.

Enhanced Automation and Robotics Integration

Laser welding seamlessly integrates with advanced automation and robotic systems, enhancing manufacturing capabilities. Automated laser welding systems offer consistent and repeatable results, eliminating human errors and improving overall product quality. By automating the welding process, manufacturers can achieve higher production volumes, reduce labor costs, and optimize workflow efficiency.

Environmental Friendliness

Laser welding is an environmentally friendly welding method due to its precise heat application and minimal waste generation. With reduced energy consumption and minimal emissions, this technology aligns with sustainable manufacturing practices and green initiatives. As companies increasingly focus on eco-conscious operations, laser welding emerges as a key contributor to minimizing the industry’s environmental impact.

The advantages of laser welding are undeniable, propelling it to become a game-changer in the world of manufacturing and fabrication. Its precision, efficiency, and versatility make it a preferred choice across diverse industries, ensuring top-notch quality and cost-effectiveness. As technology continues to evolve, laser welding is expected to play an even more significant role in shaping the future of manufacturing, bringing us closer to a world of limitless possibilities.

If you are fascinated by the possibilities of laser welding and would like to explore how Nubile S.r.l. can contribute to the success of your project, we invite you to visit our website. Learn more about our metalworking services, our experience in diverse industries, and how we can turn your ideas into tangible reality.